From expert diagnostics and preventive maintenance to retrofitting and rapid spare-part manufacturing, we consolidate all your die casting servicing under one roof. No more fragmented service—just seamless, consistent support ensuring maximum uptime.

Our Total Productive Maintenance (TPM)-aligned approach eliminates waste by proactively addressing downtime, defects, and over-maintenance. We leverage DMAIC root-cause analysis and predictive techniques to maximize your productivity, efficiency, and profitability.

Rapid-response manufacturing for both OEM-standard and expertly reverse-engineered spare parts. Each component is calibrated precisely to your machine's tolerances, ensuring reliability, accuracy, and minimal downtime.

Backed by decades of engineering insight and an unwavering commitment to quality, we specialize in delivering not just equipment — but confidence. Our servicing capabilities are known for their precision, durability, and the shortest lead times in the industry. It’s why leading foundries and PDC users rely on us to power their production.

Backed by decades of engineering insight and an unwavering commitment to quality, we specialize in delivering not just equipment — but confidence. Our servicing capabilities are known for their precision, durability, and the shortest lead times in the industry. It’s why leading foundries and PDC users rely on us to power their production.

Precision servicing and alignment of toggle mechanisms on HPDC machines to maintain optimal machine force, reduce wear, and extend lifecycle.

Rapid availability of both OEM and precision reverse-engineered parts,

including:

Expert retrofitting of outdated equipment with modern, PLC and SCADA-integrated control systems to enhance performance, safety, and efficiency.

Rigorous machine calibration and detailed quality audits, incorporating DMAIC-driven processes and TPM protocols, ensuring peak performance and reliability.

Machines serviced by our expert team consistently operate efficiently for 10-12 years, achieving measurable productivity improvements backed by well maintained lubrication systems.

We combine smart design, lean processes, and expert craftsmanship to deliver machines faster — without compromising quality.

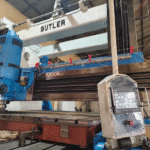

Our facility is equiped with state of the art machines such as plano milling, boring machines, lathes, horizontal drilling machines, 3 eot cranes that can life upto 25 tons etc

C-Frame Construction specially designed for vibration -free injection, this structure is essential for the production of high-precision aluminum castings.

High-Quality reconditioning: Machines we service typically operate efficiently for 6-8 years, significantly outperforming competitors whose machines fail within 3 years.

State-Of-The-Art In-House facility: we manufacture die casting machine spares such as, cylinders, closing cylinders, injection system, ejector cylinder, accumulators and Manifolds.

All operations are performed In-House, Ensuring the highest quality and faster delivery times.

121, Kenchanakuppe Village, Bidadi, Mysore-Banglore Main Road

Monday - Saturday

09:30am - 05:30pm

The point of using Lorem Ipsum is that it has more-or-less normal